WERZALIT is one of the leading european companies for innovative wood material components and industrial molded wood and wood plastic parts.

WERZALIT offers individual solutions made of high-quality wood-based materials worldwide. The product range includes facade and balcony elements, window sills and patio coverings, table tops for outdoor use and high-quality beech-wood slats as well as industrial molded parts.

Plywood slats for slatted frames are supplied to bed manufacturers as suppliers of industrial products; Semi-finished products such as plywood and veneers as well as chipboard cores for office chairs are also part of the production program. The latest product category for the construction and industrial sector is the S2 wood-polymer material.

History

In 1923, Jacob Friedrich Werz founded a small gluten glue production facility in Goppingen to supply local joiners and plywood companies.

In 1941, he took over the operation of a previous glue customer in Oberstenfeld, Ludwigsburg district, who produced deformed plywood (chair seats and backrests, plywood housing for the German radio and phono industry, etc.).

From the mid-1950s, a completely new process was developed, the later patented WERZALIT process, in which ready-made tables, serving trays, wall panelling panels and the like were made from finely machined wood, synthetic resin glue and additives. Parts are manufactured – the birth of WERZALIT wood-based materials.

WERZALIT gradually becomes the material name, the name of the process and the company name. The production know-how of the WERZALIT process is underpinned by a large number of patents. Over time, the process is also licensed at home and abroad.

Wood for sustainable products

The most important raw material for products from WERZALIT is wood. In Germany, Industrial Wood is used that comes from forests within a narrow radius of less than 100 Kilometers. The environmental managers in the house make sure that the wood suppliers are exclusively PEFC or FSC certified Forestries.

PEFC – ‘Program for the Endorsement of Forest Certification Schemes’. (Forest Certification Scheme Recognition Program) is an independent non-governmental non-profit Organization. It works worldwide for the evaluation and mutual recognition of national forest certification programs. FSC – Forest Stewardship Counsil is also a world wide non profit organization like PEFC

Economic, Ecological and Social Standards

Forest certification can only be successful if PEFC certified wood reaches the end user. This also requires certification of the timber industry in the product chain. WERZALIT has been cooperating with certified forest companies for years. The primary objective of PEFC is the documentation and improvement of sustainable forest management with regard to economic, ecological and social standards.

Safety for Responsible Action

The PEFC certificate gives buyers of wood products the assurance that manufacturers are promoting the sustainable management of forests through their actions. It identifies WERZALIT as a responsible and ecologically acting manufacturer.

Corporate Policy

Innovative construction elements and industrial mouldings made of high-quality wood materials for living and building. Individual solutions combined with innovations – this is our company claim. WERZALIT products are also characterised by a high degree of innovation – visible in numerous patents.

The basic philosophy of our company is the manufacture and supply of high-quality and durable products. This also applies to our services, from the first contact with the customer to advice and customer service. As a manufacturer, we feel committed to the idea of sustainability and resource conservation.

WERZALIT’s corporate policy provides the framework for setting and evaluating goals. It involves our employees in the continuous improvement of quality. Every employee is responsible for the quality of his or her work!

Quality and energy management are an indispensable part of our corporate culture and a management task at all levels of the company. Top management provides all the resources and information necessary to implement the corporate policy and achieve the strategic and operational goals. EN ISO 9001 and EN ISO 50001 are the foundations of our management system. By constantly improving our products and processes, by continuously carrying out tests and measurements, and by cooperating with public institutions and testing institutes, we ensure that:

- the quality of our products and services makes a decisive contribution to the satisfaction and success of our customers.

- we prefer to purchase wood from sustainable forestry close to the location.

- energy-conscious procurement and economical use of energy protect the environment and the living space entrusted to us and improve energy-related performance.

- we take all measures to minimise environmental impacts.

- the safety of our employees is guaranteed at all workplaces.

- our employees regularly participate in training and further education measures, which additionally promotes quality awareness.

- responsible behaviour towards society, the environment and the region, both within and outside the company, forms an integral part of our quality thinking.

- the improvement of energy-related performance is successfully pursued and implemented.

- compliance with the legally applicable requirements is adhered to.

The integrated management system with management manual and additional documents is a guideline for the implementation of the management system and a binding requirement for all employees.

The most beautiful connections made of wood

WERZALIT uses Modern Materials with Extremely Positive Material Properties – from Durability to Environmental Friendliness.

Made for a Long Life

WERZALIT materials pass extreme endurance tests such as swelling tests and tests for paint removal resistance during ongoing production. In special climatic chambers, the material is subjected to a wide range of influences and climatic fluctuations between -20°C and +70°C. Auf den WERZALIT Versuchsfeldern trotzen beispielsweise Testfassaden seit 30 Jahren Wind und Wetter. WERZALIT facade profiles have even been tested for seismic safety.

WERZALIT Holzwerkstoff

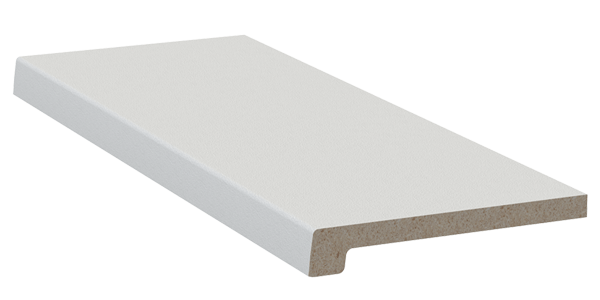

The proven WERZALIT wood-based material is used in our balcony and facade profiles, window sills and table tops. A patented manufacturing process combines the natural properties of wood with the resistance of high-quality resins. The coating is permanently bonded to the highly compressed wood material.

S2 Wood-Polymer Material (WPC)

Terrassenprodukte werden aus dem S2 Holz-Polymer-Werkstoff (WPC) gefertigt. With S2 WERZALIT has developed a material that combines the advantages of wood and plastic. It is as easy to work with as wood and is at the same time as malleable or flowable as thermoplastic. The extrusion and injection molding technology previously reserved for plastics is also used for wood at S2. S2 has a distinctive fiber structure made from colored polymer and wood fibers.

Laminated Plates

WERZALIT balcony cladding panels consist of several cellulose sheets that are impregnated with resin and pressed into a homogeneous panel. The core tracks give it the stamina necessary for further processing. The decor paper soaked with melamine resin, one of the hardest resins, and the transparent overlay form an indestructible surface. The structure of the panel is precisely matched to use as facade and balcony cladding.

The most important thing about WERZALIT

Company Datas

• Founded in 1923

• 440 employees

• Annual turnover 2022 of 56 million euros

Central Administration Headquarters

Bahnhofstraße Gernrode 45

37339 Gernrode

Manufacturing

• 37339 Gernrode/Niederorschel (Thüringen)

• 17300 Rochefort (Frankreich)

• 305500 Lugoj (Romania)

Sales Orientation

Worldwide

Awards

Our Goals

WERZALIT is the first choice for our customer.

Our Mission

Sustainable product based on wood for your better satisfaction

Our Vision

We intend to provide our customers with best service from beginning to end.