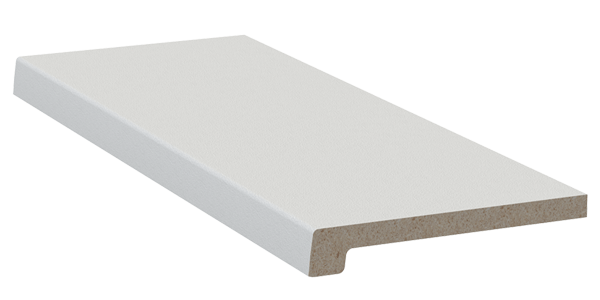

Moulded wood particle parts

Key Benefits

- Dimensional stability and high strength

- Made from renewable resources

- No subsequent processing or extra drilling required

- No excess material consumption

- Pressing process allows for unusual shapes

- Fire protection class 2

- PEFC certified

The wood that takes on any shape

With their three-dimensional formability, moulded wood particle parts are unique among wood materials. This property opens up countless possibilities that cover the full range of conventional wood design work.

In perfect form

Moulded wood particle parts hold their shape extremely well and have very high strength. The pressing process allows a number of shapes that are not available with other wood materials, such as realising varying wall thicknesses within a single piece. It also produces special properties – for example, WERZALIT moulded wood particle parts satisfy fire protection class B2.

Areas of application

Moulded wood particle parts are now used in a wide range of areas. Pallets in the packaging industry, bungs in the paper industry and cushion mounting boards for office chairs in the furniture industry have found an optimal material in moulded wood. Many more applications are also possible.

Dimensions and Properties

| Density: | 925 kg/m 3 |

| Flexural strength: | 30-40 N/mm 2 |

| E-module (bending): | 4500-5500 N/mm 2 |

| Charpy impact strength: | 16 kg/m 2 |

| Screw extraction strength: | 100-150 N / mm measured at 10 mm screw depth and 4 mm chipboard screw |

| Swelling according to 24 h DIN EN 317 : | 5-7% |

Reference